A Comprehensive Overview to the Kinds Of Ceramic Coating on the Market

Ceramic finishes have arised as a critical solution throughout different industries due to their special residential properties and applications. As we discover the distinctive attributes and applications of these finishings, the ramifications for efficiency and durability become increasingly apparent, raising inquiries about which type might finest fit your requirements.

Understanding Ceramic Coatings

Ceramic layers are advanced protective options that have actually acquired appeal in numerous markets, especially in vehicle and aerospace applications. These coatings contain a fluid polymer that, when healed, forms a long lasting, hydrophobic layer on the surface area of the substratum. This layer supplies boosted resistance to ecological pollutants, UV radiation, and chemical direct exposure, thus prolonging the life and aesthetic allure of the underlying product.

The fundamental component of ceramic finishings is silica, which adds to their firmness and resilience. The application procedure usually entails surface preparation, application of the coating, and curing, which can be achieved via heat or UV light. As soon as treated, ceramic coverings display outstanding bonding homes, permitting them to adhere strongly to a variety of surface areas, consisting of metals, plastics, and glass.

Along with their protective functions, ceramic coverings likewise provide ease of maintenance. Their hydrophobic nature reduces the adherence of dust and grime, making cleansing easier and much less constant. On the whole, the fostering of ceramic finishings represents a considerable development in surface area security technology, supplying both functional and visual advantages throughout multiple fields.

Types of Ceramic Coatings

Numerous kinds of ceramic layers are readily available, each made to fulfill particular performance demands and applications - ceramic coating sarasota. The most typical kinds include:

Silica-based Coatings: These coverings mainly contain silicon dioxide and are known for their resilience and chemical resistance. They are widely made use of in automobile and commercial applications.

Titanium Dioxide Coatings: Prominent for their photocatalytic residential or commercial properties, titanium dioxide finishings are usually used in settings where self-cleaning and antifungal homes are desirable, such as in building products and automobile surfaces.

Zirconia Coatings: Identified by their high-temperature stability and thermal resistance, zirconia finishes are utilized in applications such as generator engines and high-performance automobile components.

Alumina Coatings: Exhibiting excellent solidity and thermal security, alumina coverings are often made use of in wear-resistant applications, including reducing devices and industrial machinery. - ceramic coating sarasota

Hybrid Coatings: Incorporating the homes of numerous products, hybrid finishings supply improved efficiency attributes, making them suitable for one-of-a-kind and demanding applications.

Each sort of ceramic coating serves unique objectives, allowing customers to choose the most suitable solution based upon particular environmental conditions find out here now and efficiency requirements.

Advantages of Ceramic Coatings

Ceramic layers, in certain, deal countless advantages that make them significantly preferred among makers and consumers alike. These finishes are resistant to scratches, chemicals, and UV rays, making sure that the underlying surface area stays protected over time.

Along with toughness, ceramic coatings offer superb hydrophobic buildings, enabling easy cleansing and upkeep. This water-repellent nature lessens the adherence of dust, gunk, and various other pollutants, which can extend the visual appeal and functionality of the surface. Moreover, ceramic finishings can significantly enhance thermal resistance, making them perfect for applications that endure high temperature levels.

Application Refine

When applying ceramic layers, a careful strategy is crucial to achieve optimal outcomes. A clean surface makes certain proper attachment of the layer.

As soon as the surface is prepped, the next action is to apply the ceramic finish. This can be done making use of an applicator pad or a microfiber cloth, making certain also insurance coverage. It is critical to work in tiny areas to you could try these out keep control and prevent early treating. The coating ought to be used in slim layers, as thicker applications can result in uneven finishes.

After application, the covering calls for a specific healing time, normally varying from a couple of hours to a complete day, relying on the item. During this time, it is vital to stay clear of direct exposure to wetness or impurities. A gentle buffing may be needed after treating to improve the gloss and get rid of any high places. Following these actions diligently will optimize the performance and longevity of the ceramic finish, offering a sturdy safety layer home for the surface.

Maintenance and Long Life

To make sure the long life and effectiveness of a ceramic covering, normal maintenance is crucial. Ceramic coverings, understood for their longevity and safety top qualities, need certain treatment regimens to optimize their life expectancy and efficiency.

In addition to regular washing, regular inspections are essential. Seek indicators of wear or damage, such as hydrophobic homes decreasing or surface area imperfections. If needed, a light gloss might be related to rejuvenate the finishing without stripping it away.

Moreover, the application of a booster spray can improve the finish's hydrophobic impacts and recover its gloss. This is especially valuable for finishes that have actually been in use for a prolonged period. Ultimately, by adhering to these maintenance practices, one can substantially extend the life of a ceramic finish, making sure that it continues to give ideal protection against ecological factors and keep the aesthetic charm of the automobile.

Final thought

Mason Gamble Then & Now!

Mason Gamble Then & Now! Michael J. Fox Then & Now!

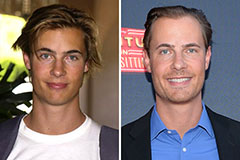

Michael J. Fox Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now! Peter Billingsley Then & Now!

Peter Billingsley Then & Now!